The motor’s significance in the world of automobiles cannot be overstated, and understanding how an electric car motor functions is a journey that unveils a tapestry of technological marvels and scientific intricacies. As we navigate through the historical context, we come to appreciate the relentless pursuit of innovation that has led us to the electric vehicle revolution. The evolution of electric motors serves as a testament to the tenacity of human ingenuity and its commitment to creating a more sustainable and efficient future for transportation. How does an electric car motor work?

How does an electric car motor work?

Step 1: Power Source

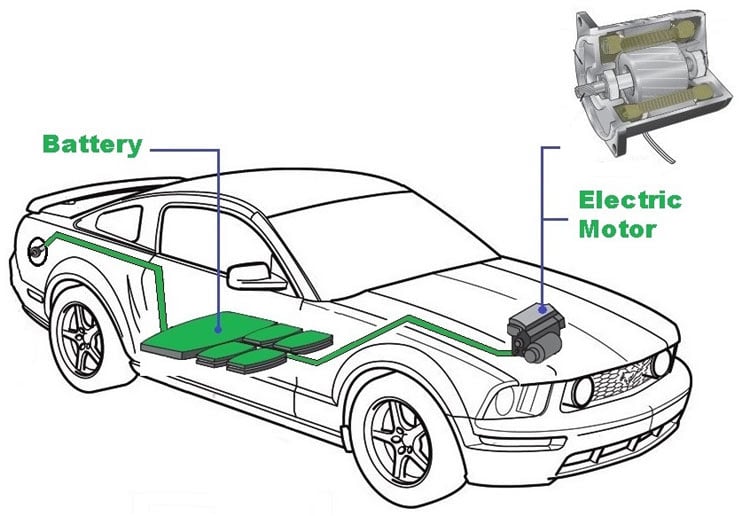

At the heart of an electric car’s propulsion system lies a sophisticated electric motor. This motor is a fundamental component responsible for converting electrical energy into mechanical motion, propelling the vehicle forward. The electric motor draws power from a high-capacity battery pack, typically mounted within the vehicle’s chassis. These batteries store electrical energy generated from an external power source, such as a charging station or a home-based electrical outlet. This stored energy is crucial for the vehicle’s operation, acting as the lifeblood that fuels the entire electric propulsion system.

Step 2: Battery Chemistry

The type of battery used in electric vehicles is a vital consideration. Lithium-ion batteries are the most common choice due to their high energy density, reliability, and ability to maintain a consistent voltage. These batteries consist of multiple cells connected in series and parallel, effectively providing the necessary voltage and current to power the electric motor. The chemistry within these batteries allows for the reversible flow of electrons, facilitating the storage and release of electrical energy.

Step 3: Power Inverter

The power generated by the battery, however, is in direct current (DC), which is not suitable for driving the electric motor efficiently. To address this, a power inverter comes into play. The inverter is an electronic device that converts the DC power from the battery into alternating current (AC). This AC power is what the electric motor requires to operate optimally. The inverter also plays a role in controlling the motor’s speed and torque, making it a crucial element in regulating the vehicle’s performance.

Step 4: Electric Motor Types

Electric cars utilize various types of electric motors, with the most common being the brushless DC motor (BLDC) and the induction motor. The choice of motor type depends on factors like efficiency, cost, and desired performance characteristics. BLDC motors offer high efficiency and precise control, making them a preferred choice for many electric vehicles. Induction motors, on the other hand, are known for their simplicity and reliability but may have slightly lower efficiency in certain applications.

Step 5: Mechanical Transmission

In traditional internal combustion engine vehicles, a complex gearbox with multiple gears is used to regulate engine speed and power output. Electric vehicles, however, often employ a much simpler mechanical transmission or even go without one entirely. This is due to the electric motor’s ability to generate a wide range of torque and RPM (revolutions per minute) without the need for extensive gear shifting. Some EVs use a single-speed transmission, which simplifies the drivetrain and reduces maintenance.

Step 6: Power Distribution

The electrical power generated by the battery and modified by the inverter is distributed to the electric motor through a series of cables and connectors. Efficient power distribution is crucial to ensure that the motor receives a consistent and stable supply of electricity. This network of cables and connectors must be designed to handle the high currents and voltages involved in an electric vehicle’s operation, all while minimizing power losses and heat generation.

Step 7: Motor Controller

The motor controller is the brains behind the operation of the electric motor. It plays a pivotal role in regulating the flow of electrical current to the motor, ensuring that it operates within safe and efficient parameters. The controller receives input from various sensors, such as throttle position and wheel speed, and adjusts the motor’s output accordingly. This dynamic control allows for features like regenerative braking, which can recover energy during deceleration and return it to the battery.

Step 8: Regenerative Braking

Regenerative braking is a unique feature of electric vehicles that allows them to recapture energy during deceleration and braking. When the driver lifts off the accelerator pedal or applies the brakes, the electric motor switches to generator mode. In this mode, the motor converts the vehicle’s kinetic energy back into electrical energy, which is then fed back into the battery. This innovative system enhances the vehicle’s overall energy efficiency, extending its range and reducing wear on the traditional friction brakes.

Step 9: User Controls

The driver’s interaction with the electric car motor is facilitated through user controls. Accelerator pedals and brake pedals work similarly to those in conventional vehicles, but the driver experiences a notably different sensation. Electric cars are known for their smooth and near-silent operation, as the electric motor provides instant torque and operates with reduced noise compared to internal combustion engines. The driver can also adjust the vehicle’s performance characteristics through different driving modes, which can alter power delivery and efficiency.

Step 10: Performance and Efficiency

The electric car motor’s performance and efficiency are determined by a multitude of factors, including the motor’s design, the battery’s capacity, and the vehicle’s weight and aerodynamics. Electric vehicles are celebrated for their swift acceleration and minimal greenhouse gas emissions. However, to ensure optimal performance, it is essential for manufacturers to strike a balance between power output, battery capacity, and energy management systems. Consequently, continuous innovation and technological advancements play a crucial role in refining and enhancing the operation of electric car motors.

Electric Car Motor Interesting Facts

1. The Basics of Electric Motors

Electric motors are a ubiquitous presence in modern life, silently powering a myriad of everyday devices and machines. At their core, these marvels of engineering operate by harnessing the principles of electromagnetism. A crucial distinction lies in their operation, which involves a stationary part known as the stator and a rotating component known as the rotor. The stator relies on a current, creating a magnetic field, while the rotor’s motion is dictated by the displacement of this magnetic field, effectively setting the motor’s speed.

2. The Pervasiveness of Electric Motors

In our contemporary world, electric motors have become an inseparable part of our daily existence. Their utility spans an extensive spectrum, with most applications predominantly featuring direct current (DC) motors that serve a range of basic functions. These motors, often found in portable electronic devices, are renowned for their simplicity and efficiency. Directly connected to their power source, be it a disposable battery or a rechargeable one, their rotational speed is intrinsically linked to the current intensity supplied.

3. Inadequacies of DC Motors in Electric Vehicles

While direct current motors excel in various applications, they fall short when it comes to meeting the demands of electric vehicles (EVs). The trifecta of power, reliability, and compact size, prerequisites for electric mobility, remain unattainable for DC motors. As a result, the shift towards alternating current (AC) motors becomes imperative. However, this transition is not without its complexities, necessitating the incorporation of a conversion circuit to transmute the DC supplied by the vehicle’s battery into AC.

4. The Duo of AC Motors in the Automotive Realm

Within the automotive industry, two distinct types of alternating current motors have emerged as the vanguard of electric propulsion. The first among these is the asynchronous motor, which employs an electrically driven stator to generate a revolving magnetic field. This magnetic field, in turn, entices the rotor into a ceaseless pursuit, akin to a chase that never reaches its culmination. Consequently, disjuncture surfaces between the rotor’s velocity and the magnetic field, a phenomenon christened “motor slip,” which exerts a palpable influence on the motor’s performance.

5. Synchronicity in the Synchronous Motor

In stark contrast to its asynchronous counterpart, the synchronous motor stands as a testament to perfect harmony in the realm of electric motors. Here, the rotor assumes the role of an electromagnetic participant, actively contributing to the creation of a magnetic field. In this setup, the rotational speed of the rotor maintains a direct correlation with the frequency of the power supplied to the motor. Unlike the asynchronous motor, there is no manifestation of motor slip, ensuring efficiency and precision.

6. The Duality of Electric Machines

Both synchronous and asynchronous motors share an essential attribute—they can function in reverse. This unique capability enables them to convert mechanical energy back into electricity during deceleration, exemplifying the concept of regenerative braking. This remarkable facet of electric motors, grounded in the principles of alternating current, not only enhances efficiency but also underlines their paramount role in the domain of modern transportation.

7. The Crucial Role of the Motor in an Automobile

The motor, a vital component of an automobile, serves as the very heart of this mechanical marvel. Its significance cannot be overstated, as the entire vehicular experience, from the acceleration of speed to the dynamic performance, is intrinsically linked to the motor’s functioning. The motor is the propulsive force, the engine that powers the modern automobile, and without it, the vehicle would be rendered immobile and inert.

Every twist and turn of the steering wheel, every press of the accelerator pedal, and every deceleration during braking is orchestrated by the motor’s intricate dance of mechanical components and electrical wizardry. Thus, it is essential to comprehend the inner workings of the motor, particularly in the context of electric vehicles, in order to fathom the future of automotive technology.

8. Curiosity Unleashed: Demystifying the Electric Car Motor

Curiosity often leads us down the path of innovation and progress, and it is in this spirit that one might inquire, “How does an electric car motor work?” This query, while seemingly simple, conceals a world of intricate technicalities, a fascinating realm of engineering marvels and scientific principles. To unravel the enigma of the electric car motor, we must embark on a journey through a series of innovations that have shaped this invention, evolving it to its present state of brilliance.

Our quest, therefore, is to explore the underlying mechanics and principles that govern the operation of electric car motors, uncovering the fascinating inner workings that drive the electric revolution in the automotive industry.

9. A Glimpse into the Evolution of Electric Motors

To understand how an electric car motor operates, it is imperative to delve into the annals of history and recognize that electric motors are not a recent revelation. In fact, these ingenious devices trace their lineage back to the late 19th century when pioneering inventors and engineers first began unraveling the secrets of electromagnetism.

The processes governing electric motors have been refined and perfected over time, mirroring the remarkable progress of science and technology. Since their inception, electric motors have undergone numerous transformations, adapting and evolving in tandem with the relentless pursuit of efficiency, power, and environmental sustainability. It is within this historical backdrop that we find the roots of the electric motor, which now plays a pivotal role in the propulsion of electric vehicles.

By examining this historical evolution, we gain a profound appreciation for the complex web of scientific principles, mechanical ingenuity, and technological advancements that underpin the operation of electric car motors in the contemporary era. The electric car motor is not merely a component of a vehicle; it is a testament to human innovation, a symbol of our unwavering commitment to cleaner, more efficient transportation, and a tangible embodiment of the progress we have made in harnessing the power of electricity to drive us into a more sustainable and electrifying future.

10. Synchronous Motors and Permanent Magnets

Synchronous motors, the powerhouses behind the electrification of modern vehicles, have evolved over the years to incorporate innovative technologies. One such advancement involves the use of permanent magnets in the motor’s rotor. This approach offers a remarkable advantage: the ability to operate without a continuous power supply. However, it comes with an intricate requirement – the utilization of specific metals or alloys, notably neodymium or dysprosium.

These rare earth elements, though indispensable for the efficiency of the motor, pose a challenge due to their notorious price volatility. This volatility can be attributed to the virtual monopoly that China holds on the global rare earth market. The reliance on China’s supply chain for these critical materials underscores the need for alternative solutions.

11. Exploring Alternative Solutions

Recognizing the vulnerability of relying on China’s rare earth supply, the electric vehicle industry has been exploring innovative alternatives. One such solution is exemplified by Renault’s ZOE electric vehicle, which employs a distinct approach. Instead of permanent magnets, Renault opts for an electromagnet fashioned from a copper coil in their synchronous motor design. This decision necessitates a more intricate and resource-intensive industrial process compared to the use of permanent magnets.

However, it ingeniously circumvents the problem of rare earth material supply. In doing so, it manages to strike a delicate balance, maintaining an impressive ratio between the motor’s weight and the torque it delivers. This solution represents a commendable step towards sustainability and self-sufficiency in the electric vehicle sector.

12. The Electric Power Train: A Holistic Approach

In the realm of electric vehicles, the synchronous motor, whether it relies on permanent magnets or electromagnets, is just one integral part of a larger, harmonious system known as the electric power train. This power train is the very heart and soul of an electric vehicle’s propulsion system. It encompasses various crucial components, each contributing to the vehicle’s overall performance and efficiency. The rotor and stator of the electric machine work in tandem within this unit, generating the mechanical power that propels the vehicle. However, they are not alone in this endeavor.

13. The Power Electronic Controller (PEC)

The Power Electronic Controller (PEC) assumes a pivotal role within the electric power train. This intelligent unit brings together an array of power electronics, masterfully orchestrating the motor’s power supply and the management of the vehicle’s battery. The PEC serves as the brains behind the brawn, ensuring a seamless and efficient flow of power from the battery to the motor. Its precision and control are crucial in optimizing the vehicle’s energy usage and performance. Thus, the PEC is the guardian of power efficiency in the electric vehicle ecosystem. Buy Electronic Components, lC chips, Module Darlington, Capacitor, find chips, diode, Transistors, Sensors, IGBT at Utsource.

14. Gear Motors and the Art of Adjustment

Complementing the synchronous motor and the PEC in the electric power train are gear motors. These unassuming yet indispensable components are responsible for the delicate art of adjusting torque and controlling the speed of rotation that is transmitted between the motor and the vehicle’s wheels. By allowing for precise control of the power delivery to the wheels, gear motors play a pivotal role in enhancing the vehicle’s stability and efficiency. They are the unsung heroes working behind the scenes to provide a smooth, enjoyable, and safe driving experience.

15. The Symphony of Silence and Efficiency

When you amalgamate these three fundamental components – the synchronous motor, the Power Electronic Controller, and the gear motors – within the electric power train, the result is nothing short of a symphony. This symphony orchestrates the electric vehicle’s silent yet powerful operation, delivering remarkable efficiency and, most importantly, a more environmentally friendly mode of transportation. In the grand scheme of things, this trinity of technologies makes electric vehicles not only a greener choice but also a more reliable and cost-effective option. Furthermore, it transforms the experience of driving an electric vehicle into a sheer delight, making it not just a means of transportation but a statement of the future.

More Interesting Articles

- How Does Satellite TV Work – How Does Dish Network Work?

- How Does Wifi Work? Signal | Work | At Home | Diagram

- How Does Wireless Headphones Work?

- How Does Bluetooth Work? Diagram | Physics | Technology

- Steps of How Does Radio Frequency Spectrum Work?

- How Does a Radio Work? Steps on How Radio Waves Work

- Radio Invention – History Past to Present with Timeline

- 40 Great African Inventions of All Times for the Entire World

- 12 Filipino Inventions of All Times – Inventions of the Philippines

- 25 Persian Inventions – Great Iranian Inventions of All Times

- 25 Great Indonesian Inventions that Shook the World

- Television Invention – History Past to Present with Timeline

- Airplane Invention History – Past to Present – Timeline

- The Hippocratic Oath First Do No Harm – Translation Old Modern

- 16 Examples of Disruptive Innovation – What are the Factors?

- 100 Best Inventions in the World Really Valuable

- 24 Nikola Tesla Inventions, Work, Contributions

- 33 Remarkable Inventions Took Place in the 50s

- 18 Great Aztec Achievements and Inventions

- 24 Great Inventions in the 60s That Still Exist